Civil shipbuilding

Experience in the production of special-purpose pumps for military equipment is successfully used in civilian projects. Numerous tankers, dry cargo ships, container ships, as well as port and offshore (offshore) facilities are equipped with products of "LGM", JSC.

Over the past 10 years we have been successfully implemented supply pumps for the following objects:

1) The Complex of drilling platforms of the Korchaginskoye field on the Caspian shelf of NK Lukoil, JSC ( IRP -1, IRP -2, living quarter platform -1, living quarter platform -2, central heat supply station);;

2) The complex of drilling platforms of the Filanovskoye field on the Caspian shelf of NK Lukoil, JSC (IRP, living quarter platform);

3) Jackup drilling rig «Arkticheskaya» ,Gazprom (Builder Zvezdochka, JSC);

4) Floating drill rig «Kolskaya»;

5) Portable drilling system «Chilim» ( Kaspiy, Lukoil);

6) The Platform D-6 «Kravcovskoe» , Baltika ( Lukoil- Kaliningrad);

7) Floating nuclear combined heat and power station ( Akademic Lomonosov);

8) Intake sea water System of Leningrad NPP, Sosnovoborsk;;

9) Water intake systems at the facilities of the Pacific and Black Seas.

For the construction, modernization and planned terrestrial, coastal and offshore facilities in Russia and other countries, "LGM", JSC is ready to offer:

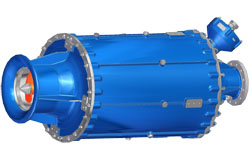

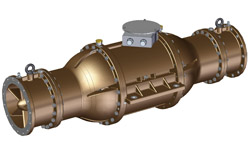

1) Supply of any pumps for seawater pumping , including - sealed and with various special requirements, including the highest category of seismic resistance. Feeding from 5 to 5000 cubic meters per hour, pressure - up to 200 meters. These include fire pumps, cooling, drainage (water supply) - including Docking pumps;;

2) Circulation pumps of high-temperature organic coolant (thermal oil, ethylene glycol solution, etc.);

3) Pumps for ballast, drainage and drainage systems, including bilge and drain water;

4) Supply of impulse aggregates used for hydraulic shock (hydraulic fracturing, etc.);

LGM, JSC developed a standard range of cryogenic pumps for the LNG pump for liquefied natural gas pumping systems with a flow rate of 100 to 2000 m3 / h, a head pressure of up to 200 m, a permissible cavitation reserve of 1-1.5 m and an electric motor power from 150 to 450 kW. This development can be applied in all projects for production, storage and transportation of LNG. Prior to this, since the 1950s, the plant has been the main supplier of cryogenic pumps for the needs of the rocket and space industry and special nuclear power engineering (liquid oxygen, nitrogen).

In 2015, JSC "LGM" supplied a batch of ENS pumps 2000/8 for the trim system of the nuclear icebreaker LR-60 "Arctic" project 22220. In Russia, such work was not conducted.

These developments of "LGM" designed to compete with foreign analogues not only on the technical characteristics, operation and maintenance, ease of use, but at a cost.

Pumping equipment, used in shipbuilding has the approval of the Russian Maritime and River Shipping Registers. The enterprise has a quality system certificate in accordance with GOST R ISO 9001-2008 No. РОСС RU.ИСМ001.К00022. In addition to the pumping equipment specified in this list, LGM acts as a supplier of a wide range of marine pumps, it develops and introduces new types of non-standard pumping equipment with the required specifications according to the customer's specifications.

The enterprise has batch production of 1,000 names of pumps in marine design.

Marine pumps

| Vertical centrifugal pumps | |||

|---|---|---|---|

| Pump type | Supply, (m3/hour) | Force, (m) | Power, (kVt) |

| НЦВ-25/20А | 25 | 20 | 4 |

| НЦВ-25/30А | 25 | 30 | 5,5 |

| НЦВ-25/65А | 25 | 65 | 11 |

| НЦВ-25/80А | 25 | 80 | 15 |

| НЦВ-40/20А | 40 | 20 | 5,5 |

| НЦВ-40/30А | 40 | 30 | 7,5 |

| НЦВ-40/65А | 40 | 65 | 15 |

| НЦВ-40/80А | 40 | 80 | 22 |

| НЦВ-63/20А | 63 | 20 | 7,5 |

| НЦВ-63/30А | 63 | 30 | 11 |

| НЦВ-63/80А | 63 | 80 | 25 |

| НЦВ-63/100А | 63 | 100 | 35 |

| НЦВ-100/20А | 100 | 20 | 11 |

| НЦВ-100/30А | 100 | 30 | 15 |

| НЦВ-100/80А | 100 | 80 | 42 |

| НЦВ-100/100А | 100 | 100 | 55 |

| НЦВ-160/10А | 160 | 10 | 11 |

| НЦВ–160/20А | 160 | 20 | 18,5 |

| НЦВ–160/30А | 160 | 30 | 22 |

| НЦВ-160/80А | 160 | 80 | 73 |

| НЦВ-160/100А | 160 | 100 | 73 |

| НЦВ-220/100А | 220 | 100 | 100 |

| НЦВ–250/20А | 250 | 20 | 22 |

| НЦВ–250/30А | 250 | 30 | 30 |

| НЦВ-250/100А | 250 | 100 | 132 |

| НЦВ-315/10А | 315 | 10 | 15 |

| НЦВ-400/20А | 400 | 20 | 30 |

| НЦВ-400/30А | 400 | 30 | 45 |

| НЦВ-630/15А | 630 | 15 | 37 |

| НЦВ-630/30А | 630 | 30 | 70 |

| НЦВ-1000/20А | 1000 | 20 | 90 |

| НЦГ-1000/20А | 1000 | 20 | 90 |

| Submersible centrifugal pumps | |||

|---|---|---|---|

| Pump type | Supply, (m3/hour) | Force, (m) | Power, (kVt) |

| НЦВп-160/10 М | 160 | 10 | 7,5 |

| НЦВп-315/10 М | 315 | 10 | 13 |

| НЦВп-630/15 М | 630 | 15 | 37 |

| ЭЦН-25ВА | 4 | 23 | 0,75 |

| Centrifugal self-priming vertical pumps | |||

|---|---|---|---|

| Pump type | Supply, (m3/hour) | Force, (m) | Power, (kVt) |

| НЦВС–25/65М | 25 | 65 | 11 |

| НЦВС–40/20М | 40 | 20 | 6 |

| НЦВС–40/30М | 40 | 30 | 8 |

| НЦВС–40/65М | 40 | 65 | 14 |

| НЦВС–63/20М | 63 | 20 | 8 |

| НЦВС–63/30М | 63 | 30 | 11 |

| НЦВС-100/30А | 100 | 30 | 14 |

| НЦВС-160/30А | 160 | 22 | 22 |

| НЦВС-250/30А | 250 | 30 | 30 |